Are you mechanically-inclined, perhaps an engineer? Are you inquisitive by nature, wondering how things tick? Do you like to fix stuff? If so, this post is not meant for you, although you might get a chuckle here and there if you decide to keep reading.

I wrote this for a different segment of the population, which I count myself a dues-paying member: the mechanically challenged. I’m pretty good with a spreadsheet, and I can make PowerPoint get up and dance. But fixing things? Not so much.

I made it through 50 good years by nurturing relationships with skilled mechanics in a variety of trades. Broken dishwasher? I’ve got a person for that. Lawnmower won’t start? I have a small-engine whisperer on speed dial. When our longtime island appliance repairman retired a few years back, I felt a surge of panic. Larry fixed nearly every appliance in our home at one time or another. How could he dare retire?

I once attempted to fix a fuel leak on our gas generator during a power outage over a holiday weekend. I mucked things up so badly I had to buy a whole new generator.

The kids retreated to their rooms whenever my battered toolbox came out of the closet. If my life were a movie, low scary music would play. Lisa would sometimes offer advice over my shoulder as I cursed and fretted. My responses were seldom civil.

This mechanical disadvantage showed up often on our sailboats. Our first boat had a temperamental Atomic 4 gas engine that would cough, sputter and die at the most inconvenient times. I would gaze at the abyss of engine space under the companionway with helpless misery. That piece of crap engine taught me a valuable lesson that lasted for the remainder of my sailing years: on a sailboat, the engine is considered a mere convenience, a backup to the real driving force of the sails.

So, you can imagine my predicament when we considered crossing over from sail to trawler. There were many great things about trawlers that excited us, but the maintenance of systems wasn’t one of them. No sails to save me. And enough mechanical equipment to run a small municipality.

While we searched for the perfect trawler, our yacht broker made sure we got a good look at the engine room on every boat we toured. What in the hell is all this stuff? I looked around and nodded, but soon made my way out of the claustrophobic space back to the light and allure of the pilothouse and boat deck.

We met other trawler captains and crew to get better acquainted with the lifestyle and the challenges they faced underway. While many were former sailors like us, they seemed to have this zeal for fixing things. Engineers and former mechanics, most of them, MacGyvers, all of them. I admired their can-do attitudes while I struggled to keep up with their engine-speak as they discussed kilowatts, heat exchangers, and hydraulics. After these encounters, I fretted about my lack of skill.

But this story has a happy ending. What follows is the journey this non-mechanic took to achieve, if not mastery, at least a pretty damn good working relationship with the many systems aboard our 43’ Nordhavn trawler. If I can do this, really anyone can.

Taking Stock

In the first few weeks we owned Indiscretion, I spent time taking stock of the equipment and machinery aboard the vessel. This involved looking into every cabinet, cubby, crawlspace, locker, and recess. Lifting floorboards under bunks, and discovering even more floorboards under those. Twisting my frame into the deep cockpit lazerette and squirming to the outer reaches, past the hydronic heating system, the inverter, and the watermaker — just looking and identifying things.

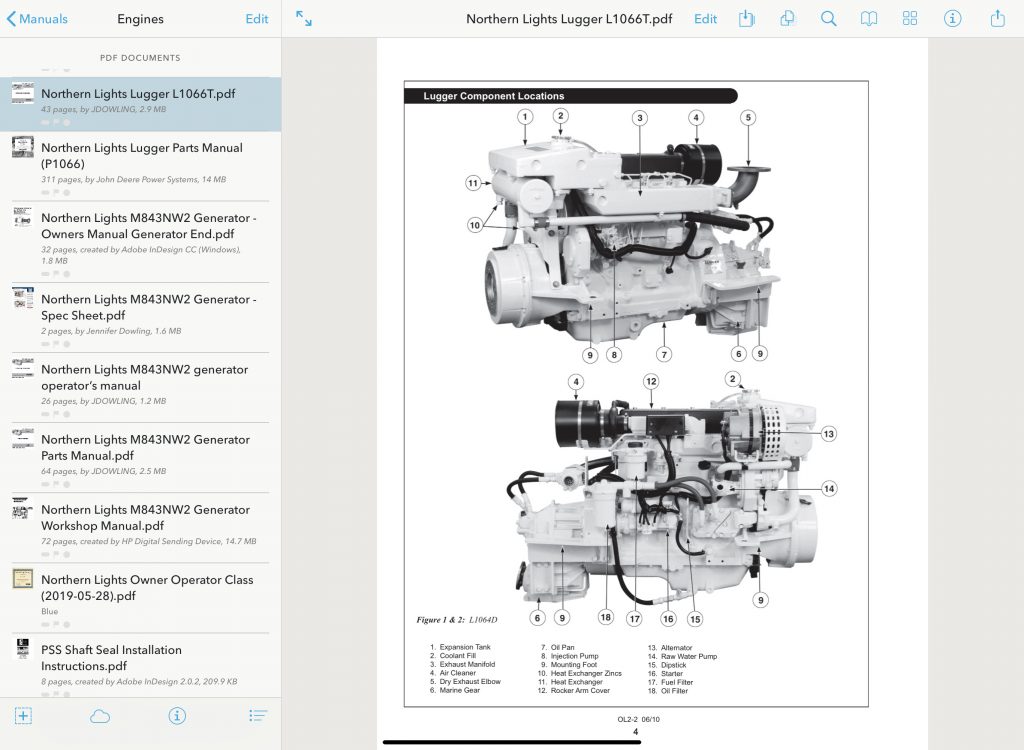

Next, I sorted through three large file boxes of equipment manuals stowed under the pilothouse settee. Our trawler came with an owner’s manual that describes practically every aspect of the ship’s operation with details on all the equipment and systems as it was commissioned. I went through the manual, section by section, and completed a second, more informed tour through the boat. This time, I sought out the equipment described in the manual and studied its use and maintenance requirements. I took the manuals home and created a digital library by downloading PDFs of the manuals if I could find them online, and if not, scanning them myself. I stored all these PDFs along with maintenance records, licenses, etc. in an app called DevonThink, which I use on a Mac, iPad, and iPhone. Having all these manuals on a digital platform means I can quickly search and access my entire library of boat records and manuals from anywhere, even when not connected to the internet. I have frequently made use of this easy access deep with the bowels of the engine room.

In My Wheelhouse

Most all of these operating manuals have a section on required maintenance for the equipment in question with instructions and frequency intervals. Ah, I thought, a perfect application for a spreadsheet to keep track of all these maintenance tasks. Here I found solid footing. The crew of MV Dirona shared a spreadsheet they’ve used as a maintenance log for their trawler. I happily began tailoring it to our boat’s systems and engines. Finally, something I could competently carry out!

Soon after creating my digital library of operating manuals, and about halfway into creating a spreadsheet-based maintenance log, I received an email from Wheelhouse Technologies (now Vessel Vanguard), a vessel maintenance software provider. I learned that the former owner of our Nordhavn had recently implemented their cloud-based system, which we were free to use for the first year, and could renew after that for a $450 fee. I knew that owners of larger trawlers swore by this system, but I wasn’t sure I needed to spend this kind of money each year on a software system I could piece together myself.

That changed after I spent time with the system, which had been configured explicitly for Indiscretion. Every piece of equipment aboard the boat was listed with operating manuals, maintenance schedules, maintenance log, and recommended spare parts for both coastal and offshore cruising. The heart of Wheelhouse is its maintenance alert system, which provides a to-do list of recommended maintenance tasks based on time or engine hours. For every task, the system includes helpful hints on how to perform it, the parts needed, and links to the appropriate manual for more detailed instructions.

Wheelhouse took the mystery away for me about the proper steps to maintain our trawler. And my accountant-brain loves a good to-do list. I’ve definitely got that with this system. When my first year free trial period had ended, I happily renewed for the peace of mind of knowing I was keeping up with the critical maintenance needs of this complex vessel.

Outfitting with Tools and Spare Parts

I soon learned that having the right tools for the job made life a lot easier. I found a list of recommended tools to keep onboard a trawler and began slowly accumulating these tools throughout our first year. Boxes would show up, and I would cackle to myself as I held up a set of ratchets, or a snake-like device meant to retrieve a dropped item in the bilge, or a strap-wrench that can grip onto oil filters with superhuman strength — who knew? All told, I spent about $2,000 on tools for Indiscretion in our first year, and I now have the tools I need to fix or maintain almost everything onboard.

Wheelhouse provides a list of spare parts to keep on hand for the various systems onboard, including annual replacement items like filters, but also parts that routinely wear out with use. I spent another $3,000 on a near-complete set of spare parts for all three engines, the watermaker, the hydronic heating system, and the other systems aboard. I tucked these treasures away in cubbies and lockers throughout the boat.

My confidence as a trawler captain grew a lot with the acquisition of these tools and spare parts. I’ve now had many chances to use the tools and have needed a few of these spare parts in the past year. That’s a good feeling.

Bending the Learning Curve

I’ve already written about the training courses we took at Northern Lights with “Lugger Bob” Senter (see here and here), but I’ll reiterate that those three days provided more value than any training I have ever received, and without these sessions, I would still be quite lost. I learned a ton from Bob and fellow trawler captain classmates and gained a whole new appreciation for the practice of preventative maintenance. But, perhaps most importantly, I discovered that trawler maintenance and repair wasn’t some dark alchemy for trained engineers. Anyone with the right tools and a little common sense can do this.

I’ve also benefited from fellow trawler owners we’ve met during our cruising. I recall struggling to get the outboard motor to lower into the water on our tender while anchored off Penrose Point. Daryl, the skipper of the beautiful trawler Cape Ross anchored next to us, must have pitied me because he motored over in his tender to see if he could help, cold beer in hand. It took him about 30 seconds to find the engine lock I had somehow overlooked (it’s really impossible to miss). I got a good laugh at myself, and we drank a beer together to commiserate about boats while we took in the beautiful bay we shared. Boat people are fantastic.

Then, of course, there’s YouTube. You know there are videos to help you repair your lawnmower and oven, but did you know that generous trawler owners also post instructional videos? One of my favorites is an engine room video from the captain of MV Cassidy on changing the oil and filters (and other repairs) on his Nordhavn 40. I watched this video during the process of buying Indiscretion, and it gave me an early boost of confidence that I could actually do this maintenance stuff. A recent video from the crew of MV Dirona showed how simple it is to check and replace the alternator belt and bearings on the main engine. There are some terrific maintenance and repair videos on MV Freedom’s YouTube site, and this video with Jeff Merrill and Kevin Jeffries of MV Red Rover inspired a lot of tool purchases. I am incredibly grateful for the time and effort these trawler owners have given to share their expertise.

And finally, there’s the Nordhavn Owner’s Group, or NOG for short. It’s a private internet discussion forum where owners post questions or problems, and other owners respond with advice or solutions. There are resident subject matter experts on specialty areas that chime in frequently. Bob Senter, for example, is a frequent contributor on engine questions. Currently, there are more than twenty thousand discussion topics in the archive — a literal treasure trove that allows me to search for whatever question or issue I have. A quick search will usually reveal a dozen or more threads, often with direct answers to my current problem. I spent many hours reading these posts and responses in my first months to absorb a portion of the collective wisdom of this resourceful group of Nordhavn owners. In the rare case where my problem wasn’t specifically addressed, I started a new topic and received some terrific feedback. I hope someday that I can develop far enough as a trawler captain to help others on the NOG.

While the NOG is a fantastic knowledge resource, it can be a little intimidating for a new skipper. One early impression I had was the sheer volume of system faults and breakdowns that can occur on a trawler. “What have I gotten myself into?” I thought to myself as I scanned problem and after problem. Reading through these caused some anxiety on our early cruises. What failures will I experience today? But, over time, I’ve come to understand a few things about this owner’s group that have helped me relax. First, of the 600+ Nordhavn yachts plying the sea today, we have one of the smallest and least complicated vessels and, relatively speaking, one of the newer models. There are many, many bigger and older vessels out there that require a whole different level of mechanical expertise and problem-solving ability. Someday, we might graduate to one of these larger, more sophisticated yachts. But not yet. Second, many Nordhavn owners take a real fancy for engineering complex solutions. For example, a recent discussion on how to resolve a frozen seacock caught my attention. One skipper carries a custom-made steel extension to connect to the end of the handle to provide more leverage. The steel was forged to fit the seacock handle perfectly. Another skipper used a ten-inch piece of plastic PVC pipe that slips over the handle and works just as well. I appreciate both approaches, but I am definitely a PVC pipe kind of guy, especially at this early stage of my trawler career.

The Deep End of the Pool

Of course, the best way to learn anything new is to do it or try to do it. Shortly after attending the Northern Lights “Captain’s Class,” we suffered a loss of electrical power, which I traced to a lifeless inverter. As our well-stocked freezer’s contents slowly defrosted, I put on my engineer’s cap. The boat’s owner’s manual and electrical diagrams led me to a switch in the lazerette, which allowed me to bypass the inverter while on shower power. This bought me some time. A search of the NOG pointed me to several troublesome T-Class fuses that could be the culprit, though physical examination of these provided no clues. Equipped with my trusty Fluke multimeter (the same model that Lugger Bob uses), I was able to determine which fuse had blown. I can’t tell you how satisfied I felt after installing a new fuse and seeing all power restored—score one for the novice.

After attending the more advanced Northern Lights “Owner Operator Class,” I plunged into the annual servicing of both our main engine, generator and wing engine. This involved changing engine oil and oil filters, replacing the coolant on the generator and wing engine, replacing all seven fuel filters, and various other annual maintenance tasks. Bob Senter gives out his cell phone number if you take his engine classes, and I admit to checking with him a few times as I proceeded with the work for his always-helpful advice.

Reflections after 18 Months

I knew going into this new life as a trawler captain would be a challenge. I’ve now serviced almost every piece of equipment on Indiscretion, and feel a growing sense of competence in the process. I know I have a lot more to learn, but I am proud of my accomplishments, especially from where I started.

One sign of my progress occurred to me while watching a boat test video of a Nordhavn 60. My former self would have marveled over the pilothouse electronics or the size of the main salon (OK, these are both still impressive!), but instead, I eyed the spacious layout of the engine room, and later fantasized about having a dedicated equipment room for all the gear that’s more challenging to access on our smaller Nordhavn. I’ve come a long way!

My newfound mechanical skills have benefited me in other unexpected ways. In the past three months, our lawn tractor, hot tub, and clothes dryer all needed repair. The old me would have called in three different mechanics. Not anymore. If I can pull apart a diesel generator in some remote anchorage, I should be able to fix a clothes dryer. With an operating manual and the proper tools, it turns out I’m quite capable of fixing just about anything.

I noted anxiety on Lisa’s face when she saw her dryer disassembled into at least forty pieces strewn across our laundry room, along with a half dozen tools and an iPad propped up on the washer playing a repair video. The hot tub and lawnmower were one thing, but she needed the dryer.

“How’s it going?” She asked.

“Well, I think I got it. It was a failed belt. I should have this back together in a jiffy.”

She walked out through the maze of parts, shaking her head and wondering if we would be buying a new dryer that afternoon. But later, after she finished a load of laundry in the newly repaired appliance, she congratulated me on my newfound mechanical capabilities.

Honestly, this must be a bit of a relief to her, knowing I’m not entirely inept at fixing things anymore. After all, she’s signed up for world cruising with me aboard Indiscretion, and we’ll inevitably face our share of mechanical adversities along the way. These newfound skills give me hope that I can keep us safe and chugging along as we voyage through remote and unfamiliar waters.

I don’t quite know how much time I spend tinkering and carrying out maintenance items on Indiscretion, but it’s not an insignificant amount. I’d guess I spend at least an hour every day I’m aboard doing something maintenance-related. And I’ve spent entire days on more extensive tasks. But this time for me is now fun, almost zen-like in its mental intensity as I work through each step like a complicated dance, usually talking aloud along the way as some form of self-encouragement. And my type-A personality loves the challenge and sense of accomplishment when I successfully complete something I wouldn’t have dared even try two years ago.

If you’re a would-be trawler captain who feels nervous about stepping into the role of mechanic and engineer aboard one of these complicated vessels, my progress should be a real comfort. If you’re on the fence, don’t let the mystery of maintenance and systems deter you.

Honestly, If I can do this, anyone can.

Great article!

Well done excellent read, your article makes me feel a bit more confident because it does look daunting.